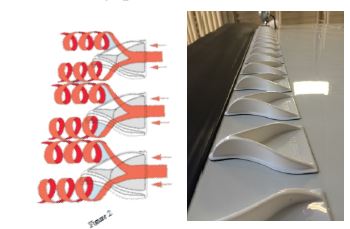

ECOFINS™ help to reduce drag effect by spinning the air as it leaves the rear of the vehicle. Each vortex lasts several meters in length, keeping the airflow controlled and restricting it from becoming turbulent. This allows the vehicle to move forward more easily as it encounters less drag. The result is a reduction in required energy (fuel) to maintain the required speed.

Each EcoFin produces two counter rotating solid body vortices that rotate at approximately 3000 rpm. These vortices are about 4 to 5 inches in diameter and trail behind several meters. They help to reduce turbulence and suction drag at the tractor-trailer gap and at the rear of the trailer.

ECOFINS SMART FUEL SAVING TECHNOLOGY SAVES UP TO 5% OF FUEL

A lack of trailer streamlining causes a partial vacuum to form at the rear of the trailer at highway speeds. This causes turbulent air in the form of large vertical (swirling motion) eddies to tumble into the partial vacuum and the large alternating (swirling motion) eddies cause the trailer to sway. Disturbances from passing vehicles or obstacles tend to amplify these (swirling motion) eddies and increase the trailer’s tendency to sway, increasing driver work load and fatigue, increasing drag and lowering fuel consumption. Streamlining the trailer by tapering consumption would be the best solution but is not practical due to a necessary reduction in trailer capacity and massive changes to loading facilities.

The large square area at the trailer rear causes a partial vacuum to form as the vehicle moves through the air at speed. These are usually devices

that physically alter the trailer rear by using inflatable sails, fiberglass boat tails or rigid metal panels that extend to taper the trailer rear. However, these devices can be cumbersome, expensive, heavy and prone to collision damage. Physically tapering the trailer or load would be the best solution but is not feasible due to trailer capacity and loading operations.